Resistor networks, also known as resistor arrays, are electrical components that comprise multiple resistors connected in a circuit pattern. These devices serve as voltage dividers by splitting the overall voltage in the circuit into smaller amounts. Future Electronics is a leading distributor of resistor networks. Read on to learn more about these circuit components. The advantages of resistor networks are described below. Aside from their versatility, they offer some benefits.

Resistor networks equalize thermal conduction:

A resistor network is made to equalize the temperature of a surface. The resistance of a conductor varies with its physical configuration and material properties. Thicker, shorter wires have less resistance than long, thin ones. In addition, Q measures the amount of heat flowing through a conductor. The temperature difference between two connected objects end-to-end is called the Fourier coefficient.

The ratio of thermal resistance to heat transfer rate are ideal for as an analogy to Ohm’s law for electrical circuits. The temperature difference acts as the driving function of heat flow. The Fourier equation, derived from an electrical circuit theory called Ohm’s law, is also helpful for calculating the heat transfer rate. It assumes one-dimensional heat transfer across a resistance element, which decreases its accuracy when the problem becomes multidimensional.

Equalize Airflow:

The major respiratory systoles are located in the nasal and oral portals. They prevent the laminar flow of inspiratory air and facilitate mucosal contact and mixing. These components determine the distribution of oronasal airflow. Aside from resistors, nasal airflow is also influenced by structural and microvascular elements. These elements are measured during rhinomanometry and rhinoscopy.

High common-mode rejection:

To achieve optimum common-mode rejection, resistor ratios must be equal. In addition, the values of all resistors should be stable over a wide operating temperature range. Monolithic devices, such as Analog Devices’ AD8221 and AD628, are convenient building blocks for high-frequency designs, but they are not always tailored to meet application needs. To meet their unique requirements, resistor networks must be designed with proper knowledge about the relationship between resistor values and common-mode rejection. This article will cover some critical factors that make resistor networks well-suited for high CMR.

How does the resistor work?

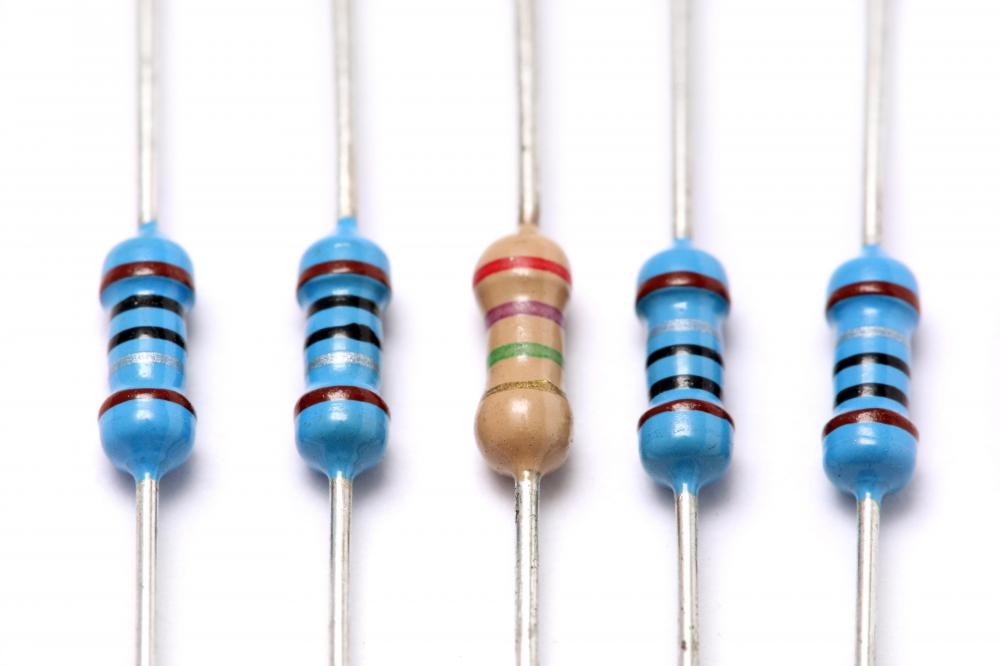

To understand how resistor networks work, let’s first understand the difference between thick and thin film networks. Thick-film resistor networks are a better choice for high-frequency applications because they have tighter tolerances than thin-film resistors. Thick-film networks are made by screen-printing resistive ink onto a substrate. As a result, they have better resistor-to-resistor matching and greater temperature coefficient tolerances than their thinner-film counterparts.

To increase CMRR, resistor networks are utilized in parallel. The first resistor pairs are connected to the bases of the other transistors. These two transistors are in an emitter-follower configuration. Their emitters are connected to a source of l2 volt potential, while the second resistors are connected to the source of +12 volts. A phase lead network containing several resistors can compensate for phase delay, thus ensuring the best common-mode rejection.

Simplify the actual production process:

Resistor networks are highly advantageous in many ways. They are an excellent choice for multiple resistors, such as gain-setting resistors, and have inherent matching to temperature shifts. Moreover, they are ideal for sensor-related applications where a common thermal substrate is essential. While discrete resistors can deliver close TCR matching, they are not as effective at cancelling drift-related errors.

Resistors can be marked numerically and sized in a geometric progression. Each new value will be greater than its predecessor by a fixed multiplier or percentage. This multiplier matches the tolerance range; for example, 1.5 times the range tolerance will cover a decade in six values. However, it is impossible to guarantee that a given resistor will be the correct value for a given application.

The complexity of Resistors:

Resistor networks are often manufactured using a simplified packaging and processing process. These processes simplify the manufacture of large quantities of resistors and, in turn, lower the cost of production. The complexity of a resistor network is a crucial factor, which requires an optimized solution for cost-effectiveness. A highly optimized resistor network will provide an improved small-volume part, such as the smallest size and smallest possible I/O pitch.

A series of resistors creates a voltage divider and a current source. In a parallel circuit, all the resistor’s leads are connected. The potential drop across all the resistors is equal in a series, but the current through a series of resistors may vary. The parallel connection allows the currents to vary based on the resistor values.

Reduce PC-board traces:

PCBs are the backbone of electronic components and appliances. But how do you create a PCB? Here are a few essential tips. Read on! – PCB traces must be wide enough to fit all the components on the board. Then, you can increase the trace width to reduce the resistance on the trace. You can also experiment with different ohm levels to find the best value.

PCB traces must be at least the width of a conductor, but the ratio of internal and external layers is also essential. It is not recommended to make internal or external trace layers wider than required. However, it is not a bad idea to make the traces longer if the overall length of the PCB is longer than required. The width of the traces is also affected by the ambient temperature and the maximum current flowing through the circuit.

Resistor networks are an excellent solution for space considerations. They can be placed in a 1210 package. Compared to a single package of resistors, these networks can save space on a PCB. However, they also increase the risk of noise pickup. Hence, resistor networks should be placed in groups to reduce the PC-board traces. And remember that it is always best to consult a PCB design expert before making any final decisions.

Reduce cost:

Resistor networks have several benefits. They reduce cost by reducing part count, simplifying assembly, and lowering BOM. Resistor networks are also easy to produce, requiring only a single pick and place step to put them on the board. However, some drawbacks do exist. First, they reduce the speed of assembly. The second benefit of resistor networks is that they reduce board space and BOM.

High-density resistor networks combine stability and reliability. They also have an extensive feature size and are manufactured using self-passivating tantalum nitride film technology. These characteristics make resistor networks suitable for demanding applications. They also improve temperature tracking performance and are common in sensor-related applications. Resistor networks reduce cost by eliminating the need for external thermal substrates and provide inherent matching to temperature shifts.

Share Substrate:

A resistor network shares the same substrate as other components. This prevents crosstalk between the individual resistors. It also minimizes thermal impact, a common problem associated with silicon-based resistors. However, one disadvantage is that resistor networks often have a thermal “shadow” zone with marginal airflow. In these situations, thermal derating may be necessary. Ultimately, resistor networks can be very helpful in cutting board layout and circuit design.

A resistor network can be manufactured in a variety of ways. Several fabrication processes are available, and different resistances are the choices. For example, chip-type resistor networks are manufactured on pre-formed ceramic substrates. They are relatively inexpensive and can be produced to an I/O pitch of 25 to 32 mils. However, this method cannot produce high-density resistorsand is not suitable for thin-film manufacturing processes.